Hydraulic cylinders are widespread solutions in industries like cylinders inc of the most diverse segments. They are equipment that facilitates the processes that involve mechanical force through a system that uses energy from the pressure of fluids. Because it is a product widely used in industries, catalog hydraulic cylinders are in high demand.

In addition, hydraulic cylinders carry out very high-pressure processes, which can present a high risk if their maintenance is not carried out correctly.

The Importance Of Checking Hydraulic Cylinders In The Catalog And Maintenance Of This Equipment

Hydraulic Cylinders catalog indicates that these items are made to work in environments and extreme situations; however, the fatigue of the parts and the useful life of the components makes them need maintenance and repairs at specific times. Among the leading causes of maintenance and repair are the following:

- Sealing problems: whether due to breakage or dryness, the sealing of hydraulic cylinders can leak, which causes it to lose pressure, and affects its operation as a whole;

- Bent rods and cracked or swollen shirts: visible to the naked eye, this type of maintenance must occur by replacing the part, whenever it is reconditioned, ensuring maximum efficiency after maintenance;

- Wear on the Stem: to prevent fluid leakage, reducing the equipment’s useful life. In such cases, replacement of the Stem, as well as its seals, is necessary.

The companies that work with this equipment present a catalog of hydraulic cylinders with several options and offer maintenance and repair services. Specialized companies recognized by the market comply with the standards established for the segment, offer guarantees and provide only high-quality materials.

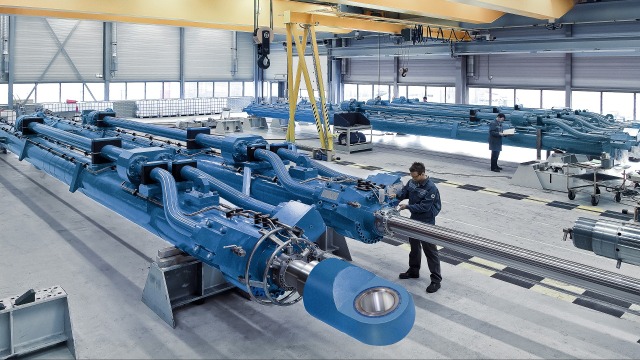

Double Acting Hydraulic Cylinders

The hydraulic double-acting cylinders convert hydraulic energy into mechanical energy and are widely used in the industry and articulating various machine systems. The application of double-acting hydraulic cylinders is very efficient. It obtains excellent results, thanks to their technical characteristics that are very specific and their dimensions that strictly follow the NFPA and ANSI B93-15-1981 assembly standards.

Advantages, Types, And Technical Details Of Double Action Hydraulic Cylinders

The double-acting hydraulic cylinders at cylinders inc have different diameters, in addition to fourteen types of mountings, they have optional damping systems at either end or both ends, and their fluid is mineral hydraulic oil. There are three types of hydraulic cylinders: Single Acting, Double Acting, and Telescopic.

With a high-strength, chrome-plated, and polished steel rod, the double-acting hydraulic cylinders’ primary function is to ensure a smooth and scratch-resistant surface, guaranteeing excellent sealing and longer service life.

Through rigorous quality control, the double-acting hydraulic cylinders have liners with a perfect pattern of alignment and surface finish; this excellent level of finish means less internal friction, causing the life of the seals to be extended.

Comments are closed.